|

1. Crude Oil Storage

Crude oil arriving at the refinery is stored in large cylindrical tanks until it can be processed. To eliminate an air gap, which would allow the build-up of volatile gases, these tanks have a floating top which sits on the surface of the crude oil. This floating top gives an indication of the volume of oil contained within the tank; in this image, four tanks are almost full, one is half-full and three are almost empty.

|

|

|

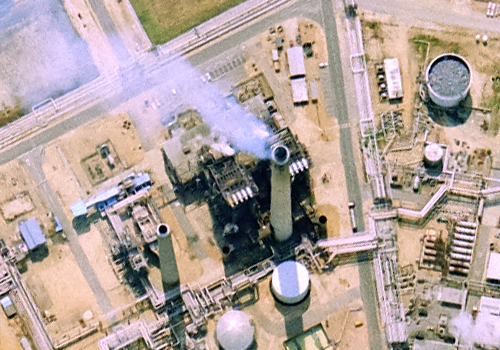

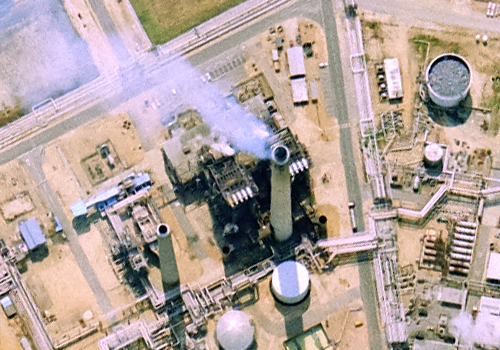

2. Processing Area

Crude oil is a mix of different hydrocarbons known as fractions. In the processing area these fractions are refined into a variety of products by separation (or fractional distillation), catalytic conversion, purification and blending.

|

|

|

3. Semi-refined and Refined Storage

After processing, the refined products are stored in cylindrical tanks with floating, flat, domed or peaked tops. These tanks are generally much smaller than those used for the storage of crude oil.

|

|

|

4. Gas Storage

Gas is stored under pressure in specially-designed spherical, spheroidal, blimp or bullet-shaped tanks. The spherical tanks seen here at Fawley are known as the Seven Sisters and contain butene.

|

|

|

5. Distribution

Oil is brought into, and shipped out of, a refinery by a combination of methods. Crude oil normally arrives by oil tanker (5c) or pipeline (5b) and is pumped into storage tanks at the refinery. After processing, refined products can be distributed to market by oil tanker, pipeline, road tanker or rail tank cars (5a).

|

|

|

6. Plant Administration

Located within the boundary of the refinery are the administration buildings, maintenance and engineering facilities necessary for the safe operation of the plant, along with associated staff car-parking areas and storage yards.

|

|

|

7. Flare Stack

Waste gases produced during processing are burnt off by a safety device known as a flare stack. This has a pilot light burning continuously at the top; if a flame is observed on imagery it indicates high activity within the processing area.

|

|

|

8. Power

An oil refinery uses a lot of electrical and steam power to drive pumps, compressors and control centres. For this reason it requires its own power station, independent of the national grid.

|

|